這款麺粉適用於任何麺包配方。 它可用於麺包機, 家庭手作麺包製作。 採用英國當地一些農場的小麦磨成。

This flour can be used in any bread recipe. It is ideal for bread machine, home and craft bread making. It is milled by using wheat from some local farms.

運送 Shipping

只送往香港本地

Hong Kong local delivery only

成分 Ingredients

小麦粉, *鈣, *維他命B3, *鐵, *維他命B1(* 根據1998年訂立麺包與麺粉法案要求的補充品)

Wheat flour, *Calcium, *Niacin, *Iron, *Thiamin (*Supplements required by law under The Bread and Flour Regulations 1998)

原産地 Country of Origin

英國 United Kingdom

品牌 Brand

威塞克斯磨坊 Wessex Mill

規格 Specification

重量

Weight

1.5 公斤/Kg

高筋白麺粉

Strong White Bread Flour 1.5kg

在“The Great Taste Awards”奨中獲得2星。

評語:“製作了一個完美的, 良好發酵的麺包。麺包質感和口味都很好。”

Awarded 2 Stars in The Great Taste Awards.

Judges comment " Made a perfect, well-risen loaf. Good crumb, texture and taste."

英國的所有麺粉都是不漂白的, 而我們也不例外。

我們従本地的農場收集小麦, 並在我們1935年建造的碾壓機上慢慢碾磨。 農場的名稱可以在包裝的背面找到。

All flour in the uk is unbleached ours is no exception.

We collect wheat from local farms and grind it slowly on our 1935 built rollermills. The name of the farms can be found on the back of the pack.

成分 Ingredients

小麦粉, *鈣, *維他命B3, *鐵, *維他命B1,

*根據1998年訂立麺包與麺粉法案要求的補充品

Wheat Flour, Calcium*, Niacin*, Iron*, Thiamin*,

*Supplements required by law under The Bread and Flour Regulations 1998

過敏建議Allergen Advice

過敏原包括穀物中含麸質, 見粗體成分。 生産麺粉的磨芳同時會處理芝麻。

For allergens, including cereals containing gluten, see ingredients in bold. Made in a mill that uses Sesame.

營養價值 Nutrition

我們的小麦来源

where our wheat comes from

従當地農場收集小麦

Collecting wheat from a local farm

検験麺粉質量

Examine Flour Quality

麺粉品質-麺筋

Flour Quality - Gluten

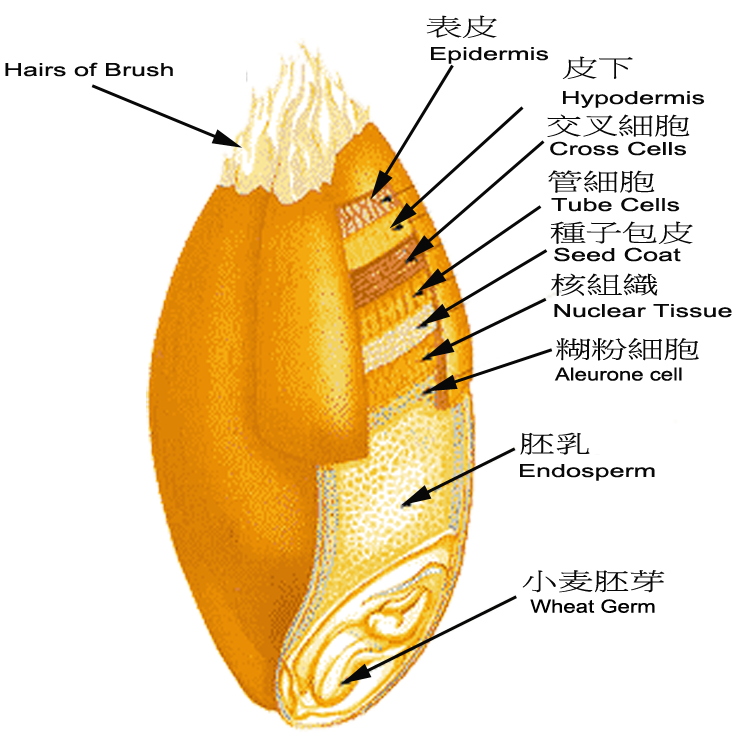

小麦的独特之處在於它是唯一包含麸質的穀物。 麺筋具有彈性, 可以保留氣泡, 當您製作麺包時, 可以把您氣泡封鎖住。

Wheat is unique in being the only grain that contains gluten. Gluten is elastic and can hold bubbles of air, when you make bread you are trapping bubbles of air.

清洗麺筋可験證質量

Washing gluten to find out the quality

為此, 我們需要一種麺筋含量高的麺粉。

蛋白質與水混合會産生麺筋。 要查看麺筋的外觀, 拿大約20克的麺團, 並在緩慢運轉的龍頭下将其洗浄。 擠壓並沖洗, 澱粉會従麺團上洗去。

To do this we need a flour that has a high content of gluten.

Gluten is made when protein is mixed with water. To see what gluten looks like take about 20 grams of dough and wash it under a slow running tap. Wash it by squeezing it and the starch will wash away from the dough.

結果

The Result

一兩分鐘後, 會剰下一個小小的麺筋球, 看起来就像香口膠。

香口膠和麺筋之間的區別在於, 麺筋在拉伸時會恢復其形狀。此特性意味著它可以容納氣泡。

為了使麺包中充滿氣泡, 要利用到麺粉中的澱粉。 在發酵過程中, 澱粉分解為糖, 酵母以糖為食糧並産生氣體。 如果麺粉磨得太輕,則不能産生足夠的澱粉顆粒以提供酵母食物来産生氣體。 磨得太重, 則會過度研磨麺粉, 這會給澱粉造成太大損害。結果使麺團發酵過快, 麺團崩潰或変得很鬆弛。

為了生産出質量一致的麺粉, 我們需要将麺粉磨砕以致澱粉顆粒破裂, 並採用麺筋含量高的小麦。 石磨麺粉無法打開足夠的澱粉,因此麺包很小且質地緻密。大多数石磨麺粉其實都是首先經石磨, 然後再經滾筒碾磨。

After a minute or two you will have a small ball of gluten left which looks like chewing gum.

The difference between chewing gum and gluten is that the gluten will try to regain its shape when stretched. This ability means that it can hold bubbles of air.

To make air to fill the bubbles in bread we use the starch in the flour. In the fermentation process the starch breaks down into sugar and the yeast feeds on it to create gas. If you grind the flour too lightly, you don't break enough starch granules to give food for the yeast to create gas. You can go too far and over grind the flour which then gives too much starch damage. This then lets the dough ferment too quickly and the dough collapses or goes very slack.

To make consistent quality flour we need to grind the flour to break open the starch granules, and use wheats with a high gluten content. Stone grinding flour doesn't break open enough starch, so loaves are small and have a dense texture. Most stoneground flour is firstly stoneground and then rollerground afterwards.

滾筒碾磨過程

The Roller Milling Process

首先, 我們清洗小麦, 取出稻草, 小種子, 例如燕麦和大麦。

然後我們加水軟化麦糠。 這可以阻止在碾磨時把麦糠変磨成粉末。

小麦的形狀奇特, 其側面有摺痕。 這意味著我們不能僅僅擦掉麦糠, 因為摺痕上會留下麦糠。

Firstly we clean the wheat, taking out the straw, small seeds like cockle and vetch as well as oats and barley.

Then we add water to soften the bran skins. This stops the bran from going to powder when we grind giving better bran flakes.

Wheat has an odd shape, it has a crease down the side of it. This means that we can not just polish off the bran, as we would be left with bran in the crease.

滾筒

Rollers

我們使用帶有小剧歯的鋼滾筒将小麦切開。 您可以在圖片頂部看到剧歯。 這個滾筒可一路滾動一路進行切割。 圖片側面的刻印可見它是在1939年2月24日製造的。

We split the wheat open using steel rollers that have small teeth in them. You can see the teeth at the top of the picture. This roll is going away to be re-cut. The stamp on the side says it was made on the 24/10/1939.

碾磨

Grinding

上滾筒比下滾筒快。 因此, 小麦粘在下滾筒上, 以便速度較快的上滾筒将其劈開。

The top roll goes faster than the bottom. The wheat sticks to the bottom roll so that the faster top roll splits it open.

第一磨

1st Break (grind)

第一次碾磨後, 我們得到麦糠, 粗麺粉和麺粉的混合物。 然後将其過篩。 由於尚未釋放所有胚乳, 因此麦糠再次被割破。

After the first grind we have a mixture of bran, semolina and flour. It is then sieved. The bran goes off to be cut again as not all the endosperm has been released.

粗麺粉(麺粉精細度的術語, 當它足夠小時, 我們才稱其為麺粉)

Semolina (term of granularity, when it is small enough we call it flour)

每次碾磨, 都會製造粗麺粉。 在有空氣流過機器上過篩。 麦糠小顆粒浮起, 粗麺粉粗粉通過篩子掉落。 您可以在圖片中看到小麦胚芽。 胚芽被碾平, 並可以在此階段篩分。 然後粗麺粉襰輸送到小滾筒再打成幼滑的麺粉。 粗麺粉非常堅硬, 因此我們通過幾次碾磨和篩分, 粉逐漸变成成麺粉。

每次碾磨, 我們都會生産出麺粉。 因此同一時間裡, 我們可生産出超過15股麺粉。 将它們全部混合在一起製成一種麺粉。 如果我們要全麦麺粉, 我們便把有麦糠和小麦胚芽也要加回去。

最終結果是質量穩定的麺粉。 它既可以吸收水(減慢麺包的陳舊速度), 並會餵食酵母菌(增加提升力)。

At every grind we create semolina. It is sieved on a machine that has air flowing through it. The small particles of bran float off and the heavy semolina falls through the sieve. You can see the wheat germ in the picture. This gets flattened by the rolls and can be sieved out at this stage. The semolina then goes to smooth rolls to grind it into flour. Semolina is very hard so we gradually reduce the semolina into flour by grinding and sieving several times.

Every time we grind we produce flour. So at any one time we are producing more than 15 streams of flour. They are all mixed in together to make one flour. If we want wholemeal then all the bran and wheatgerm are added back as well.

The end result is a consistent quality flour. It can absorb water (slows down the staling of bread) and feed the yeast (to give more lift).

水力發電

Water Power

渦輪發電機

Turbine House

去舊立新。我的兄弟一直在進行一個項目, 以重新開發我們在泰晤士河上的舊磨坊。 自従1945年被焼毀以来, 它就被遺棄了。

該項目的一部分是引入一些更緑色的熱能發電方式。 而舊的渦輪發電機(右)将成為新的開関控制室。

Out with the old and in with the new. My brother has been working on a project to redevelop our old mill site on the Thames. It has been derelict since it burnt down in 1945.

Part of the project is to introduce some greener ways of generating heat and power. The old mill turbine (right) is to become the new switch control house.

螺旋桿

The Screw

為了替代舊的臥式渦輪機, 我們購買了一個水力螺桿,該螺旋桿每小時可發電30千瓦。

該螺旋桿每秒将會消耗3立方米的水, 並會自動控制牛津河的水位。

我父親(相片中依靠著螺旋桿)記得小時候那台舊渦輪機的聲音。 如果停止了, 他常常醒來,想知道哪裡出了問題。 在那些日子裡, 由於戰爭, 它曾經以24/7運行。

您可以點撃這裡查看我們本週産生電量

To replace the old horizontal turbine, we have bought a hydro screw capable of generating 30 kw of electricity an hour.

The screw will use 3 cubic meters of water per second and will bring automatic level control to the river in Oxford.

My father (leaning against the new screw) can remember the noise of the old turbine when he was a little boy. If it stopped he used to wake up and wonder what was wrong. In those days it used to run 24/7 because of the war.

Please click Here to see how much energy we have generated this week.

正降下螺旋桿

Being lowered in place

在河水流進前安放螺旋桿到地面

The mill race floor before the river is let in

添加了隔音功能並開始運行

Sound proofing added and running

関於我們

About Us

我們是一家位於牛津郡旺塔奇的小型家庭麺粉廠。100多年来, 芒西(Munsey)家庭一直在牛津郡做碾磨工作。 該工廠目前由第四代傳人Paul經營, 而他的女児艾米麗(Emily)也正在學習成為磨坊主。

我們的麺粉是採用當地的小麦碾磨而成的, 而小麦則是従磨坊周圍的農場收集而来的。把任何小麦帶入磨坊之前, 我們通過樣品測試確保選用有最優質麺筋的小麦。由於小型工廠関係, 意味著我們可以不分批地将每個農場的小麦分開存放。 這使我們能夠仔細選擇混合小麦, 以便生産出質量一致的麺粉。

威塞克斯磨坊採用的是傳統碾磨工藝, 與現代能源密集型方法相反, 該方法是先将小麦磨成粉, 然後再對其進行脫皮。而我們慢慢地磨麺粉; 這意味著麺粉不會像其他麺粉廠那樣加熱, 従而防止了蛋白質的損壞。

我們麺粉的稠度取決於所採購的優質小麦。磨坊周圍地區生産全英國最好的小麦。我們従當地農場採購, 並且新自把撿好小麦搬上自家的貨車。

您可以包裝上查看農場名稱。

我們随時歡迎您的詢問。

保羅·蒙西

麺粉磨坊主

We are a small family flour mill based in Wantage, Oxfordshire. The Munsey family have been milling Oxfordshire for over a 100 years. The mill is currently run by fourth generation flour miller Paul, with his daughter Emily studying to become a miller as well.

Our flour is milled using local wheat that we collect ourselves from farms surrounding the mill. We ensure we only select the best wheat with high quality gluten by testing samples before we bring any into the mill. Being a small mill means we can store the wheats from each farm separately without batching. This allows us to carefully select the wheats that we mix together for the grist to produce quality consistent flour.

Wessex Mill is a traditional roller milling process, as opposed to the modern energy intensive method of debranning the wheat before grinding it into flour. We mill our flour slowly; this means the flour doesn't heat up as much as other flour mills, preventing the protein from damage.

The consistency of our flour is down to buying good wheat. The area around the mill produces some of the best wheats in the UK. We buy from local farms and pick the wheat up with our own lorries

You can find the names of the farms that we use on the packet.

We always welcome enquries.

Paul Munsey

Flour Miller

威塞克斯磨坊自豪地宣布, 新一代的家庭成員已決定要做成為磨坊主! 艾米麗将學習製麺粉和各個方面相関業務。

Wessex mill are proud to announce that a new generation of the family has decided to become a miller! Emily is going to be learning every aspect of milling and the business.

歴史

History

威塞克斯磨坊位於牛津郡的小鎮旺塔奇(Wageage)中, 由父女團隊Paul和Emily Munsey經營。 與許多英國麺粉廠相比, 這家屢獲殊榮的公司擁有悠久的製粉歴史, 艾米麗(Emily)於2017年加入公司, 延續了跨越五代的傳承。

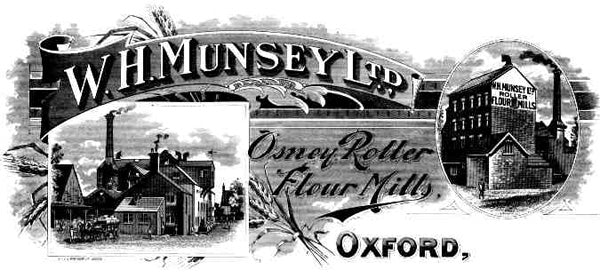

磨坊故事始於1895年, 艾米麗的曾曾曾祖父威廉·亨利(William Henry)因手足口病的嚴重爆發而被迫従剣橋搬到牛津, 因此従事耕種轉向製麺粉。最初與Archer Cowley建立合作夥伴関係, 位於牛津奧斯尼(Osney)的工廠變成了W.H.蒙西有限公司(Munsey Ltd), 威廉·亨利(William Henry)於1911年完全擁有該公司。 随著児子埃利斯(Ellis)和基思(Keith)加入生産隊伍, 家族企業継續發展, 但是由於第一次世界大戰的爆發, 製麺粉不是最必要的工作, 亨利的児子們於是離開了牛津, 前往大戰。

在戰爭中倖存下來後, 兄弟倆返回並定居継續従事磨坊工作, 但在1927年, 國家陷入戰後蕭條, 土地持有者基督教堂發出最後通碟, 這意味著芒西家族人必須買下土地或撤出磨坊。他們設法借了錢, 買了工廠後不久, 威廉·亨利便去世了。

Tucked away in the small Oxfordshire town of Wantage sits Wessex Mill, run by father and daughter team, Paul and Emily Munsey. Tiny in comparison to many of the UK's flour mills, the award-winning establishment holds a strong milling history, with Emily joining in 2017 to continue a heritage that spans five generations.

The story begins in 1895 with Emily's great great-grandfather William Henry who was forced to relocate from Cambridge to Oxford following a devastating outbreak of foot and mouth, consequently moving from farming into flour milling. Originally starting as a partnership with Archer Cowley, the mill situated in Osney in Oxford became W.H. Munsey Ltd with William Henry taking complete ownership of the business in 1911. The family venture continued as sons Ellis and Keith joined the workforce but with the outbreak of World War I and milling not being essential work, Henry's sons both left Oxford to fight in The Great War.

Surviving the war, the brothers returned and settled back into milling, but in 1927 with the country in post-war depression, land owners Christ Church issued an ultimatum meaning the Munseys must purchase the land or vacate the mill. They managed to borrow the money and shortly after buying the mill, William Henry died.

以上照片是1911年在Osney Mill拍攝的。車上的是Bill Muffin(麺粉推銷員), 左肩後面是WH Munsey, 左手是児子Ellis。

埃利斯(Ellis)和基思(Keith)一直經營工廠到1930年代, 當時已經太老了, 避免了參加第二次世界大戰的戰鬥。戰爭結束了,生意継續了下去, 但在1946年, 一場大火将奧斯本工廠燒毀了。戰後國家缺乏建築用品, 因此拒絕了在牛津重建磨坊的許可, 因此兄弟倆購買了克拉克在旺塔奇的餅乾麺粉磨坊以継續磨坊工作。

在20世紀剩餘的時間裡, 全球經済和政治形勢更加穩定, 該廠發展到第三代, 表兄弟迪克(Dick)和比爾(Bill)(分別是埃利斯(Ellis)和基思(Keith)的児子)一起, 比爾(Bill)的児子保羅(Paul)也於1982年加入公司。 今天, 比爾(Billy)的小児子東尼(Tony)經營著位於奧斯尼(Osney)的舊工廠, 該工廠於2010年被改建為房屋, 包括碼頭和水力發電螺桿。

在艾米麗(Emily)和保羅(Paul)的領導下, 威塞克斯磨坊(Wessex Mill)継續取得成功, 並發展成為今天的優質工匠麺粉生産商, 業務並遍及英國乃至全球。

This picture was taken in 1911 at Osney Mill. In the car is Bill Muffin (Flour Salesman), behind his left shoulder is WH Munsey to his left his son Ellis.

Ellis and Keith continued to run the mill through the 1930s and, now too old, avoided having to fight in World War II. The war ended and the business continued, but in 1946 disaster struck with a fire that burned the Osney mill to the ground. With the country short of building supplies after the war, permission to rebuild the mill in Oxford was denied, so the brothers purchased Mr Clark's biscuit flour mill in Wantage to continue milling.

The mill carried on into its third generation with cousins Dick and Bill (sons of Ellis and Keith, respectively), and with a more stable global economic and political landscape for the remainder of the 20th century, Bill's son Paul joined the business in 1982. Today Tony, Bill's younger son runs the old mill site in Osney which in 2010 was converted into housing and includes a marina and hydroelectric screw.

With Emily and Paul at the helm, Wessex Mill has continued to succeed and grow as the quality producer of artisan flour it is today, shipping throughout the UK, and beyond.